Exploring the Influence of Renowned Artists on Lino Printing

Pablo Picasso and Modern Art’s Printmaking Legacy: Pablo Picasso’s foray into linocut art in the 1950s and 1960s brought a fresh perspective to this traditional form, with his bold and expressive styles. Picasso’s linocuts are particularly noted for their vibrant colors and the reduction method he employed, where a single block is used to print multiple colors. This technique is a testament to the possibilities inherent in lino printing and serves as an inspiration for artists seeking to innovate within the medium.

Angie Lewin and the Natural World: Angie Lewin is a celebrated artist whose distinctive lino prints, often inspired by the clifftops and saltmarshes of the Scottish Highlands, showcase the medium’s capacity to render intricate natural details. Her work embodies a harmonious blend of the modern and the traditional, influencing lino print artists to explore the beauty in nature’s patterns.

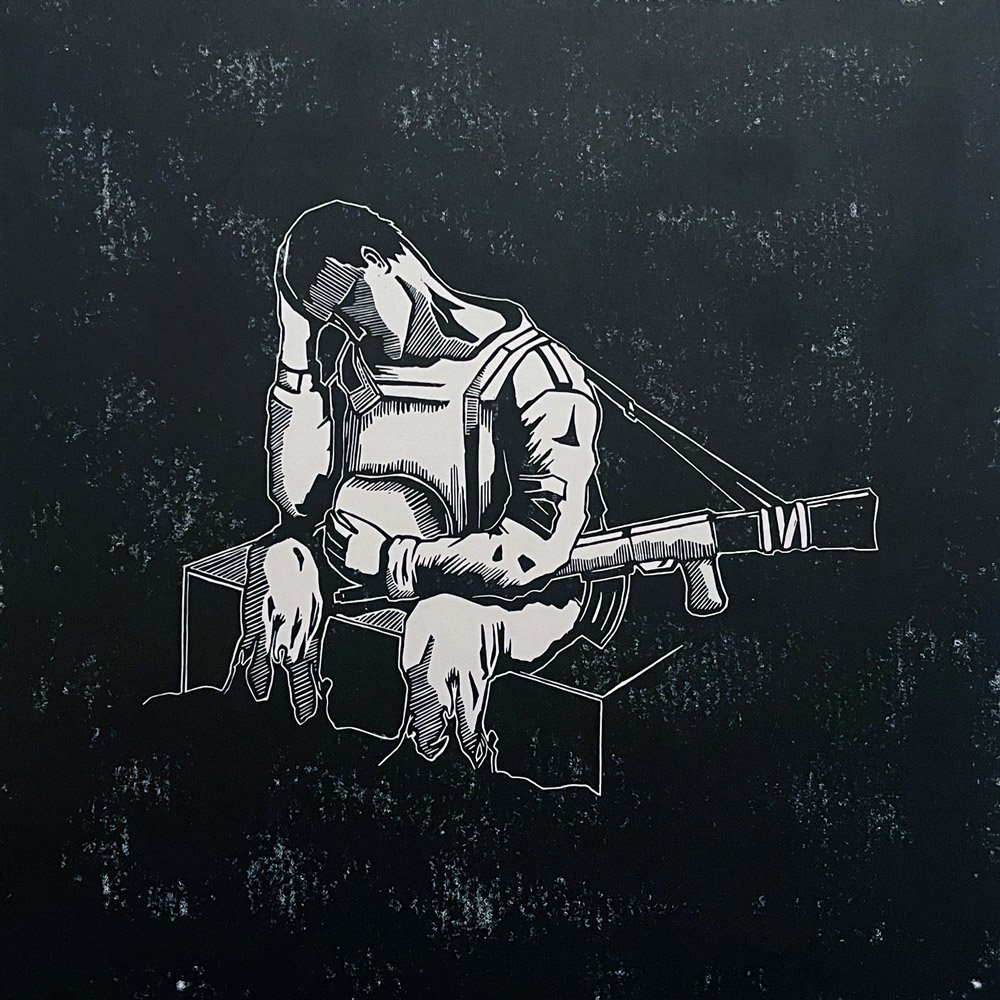

Contemporary Voices: Holly Cook, Sam Marshall, and Meg Buick: Emerging artists like Holly Cook, Sam Marshall, and Meg Buick bring new life and perspectives to lino printing. Cook’s lino prints radiate with a sense of playful narrative, Marshall’s work often features a stark, minimalist aesthetic, while Buick’s use of lino in her prints demonstrates a fluid, almost ethereal quality. These artists illustrate the medium’s versatility and its ability to convey a wide array of artistic expressions.

Read more about Lino Printing Artists

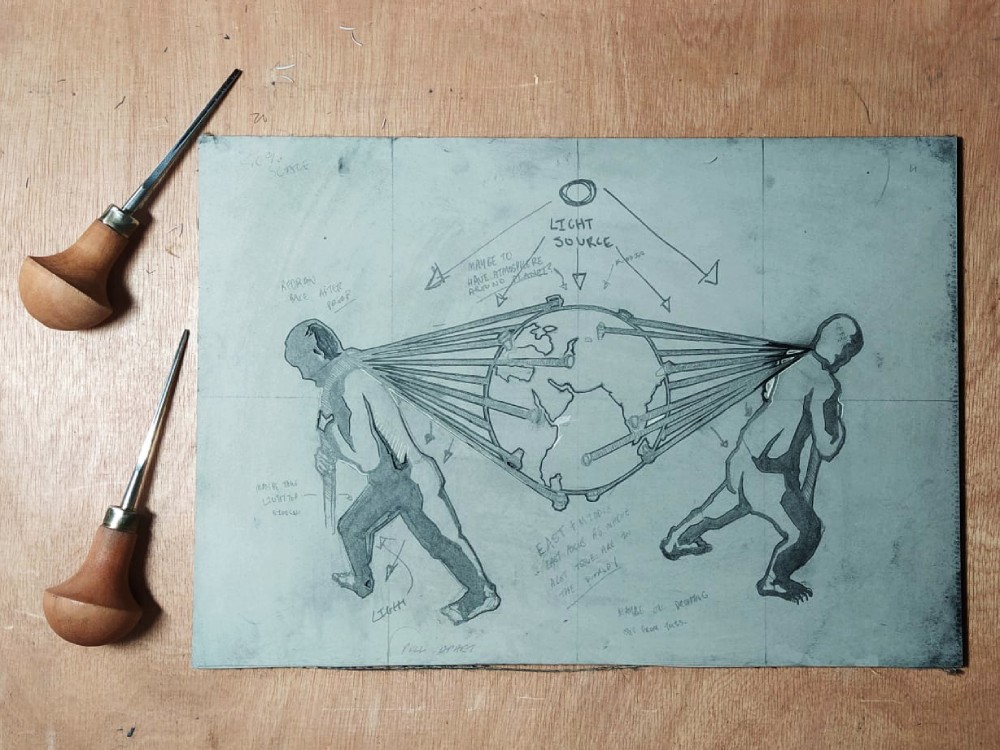

Deepening Technical Knowledge in Lino Printing Techniques

Colour Linocut’s Vibrant Complexity: Colour linocut is a complex process that involves using multiple lino blocks or layers to create a multicoloured print. This technique can produce vibrant prints with a rich depth of color.

Lino Printing within Relief Printmaking: As a subset of relief printmaking, lino printing shares its lineage with woodblock printing and engraving. It is defined by the principle of cutting away parts of the surface that are not to be inked, leaving a raised area that creates the image.

Read more about the process of lino printing

A Brief History of Lino Printing

Linoleum: From Floors to Fine Art

Linoleum, patented in the 19th century, was originally designed as a durable and affordable flooring material for a growing middle class. Made from linseed oil, pine resin, wood flour, and cork dust pressed onto burlap, its flexibility and ease of manipulation made it practical for both domestic and industrial use. However, by the early 20th century, artists saw its potential for creative expression.

German Expressionists were among the first to adopt linoleum as a medium, attracted by its affordability compared to woodcut materials. Its smooth texture allowed for fluid lines and quicker, less laborious carving. The Bauhaus movement further explored its possibilities, transforming linoleum from a utilitarian material into a revolutionary artistic tool.

After World War II, linoleum became popular in schools due to its low cost and ease of use. Its role in the DIY and craft movements of the 1950s cemented its place as an accessible medium for all levels of society. Linoleum’s journey from flooring to fine art reflects the broader democratisation of art materials and the resourcefulness of artists.

20th Century Printmaking: A New Era

The 20th century marked a transformative period in printmaking, paralleling the rise of modernism. Advances in technology and a spirit of experimentation expanded the scope of graphic arts. Artists like Pablo Picasso and Henri Matisse embraced printmaking, with Picasso creating vibrant linocuts and Matisse exploring cut-out techniques.

Printmaking also became a medium for political expression, as seen in collectives like the Taller de Gráfica Popular in Mexico. The reproducibility of prints allowed artists to reach wider audiences and engage with social issues. In the US, the Works Progress Administration (WPA) employed artists to create prints for public buildings during the Great Depression, fostering a culture of art appreciation.

By the mid-20th century, printmaking had evolved into a respected fine art form, with artists using it to explore cultural, political, and aesthetic dimensions. The period redefined printmaking, elevating it from craft to a vital medium for innovation.

Read more about the history of printmaking