Affiliate Disclosure: I only recommend products I would use myself and all opinions expressed here are our own. This post may contain affiliate links that at no additional cost to you, I may earn a small commission when you purchase. These commissions help with the running costs of this website, if you do purchase via one of the product links many thanks it is greatly appreciated!

Guide to the Top Screen Printing Exposure Lights Online!

Lights For Screen Printing Exposure

Exposure lights are one of the key tools for screen printing. Without them, you cannot expose your screens, and all your efforts would be in vain. However, with the right lights, you can expose your screens. Alternatively, you can expose your screens under natural sunlight.

Types of Lights Used to Expose Screens for Printing:

- UV lamp bulb

- Fluorescent and halogen lights are a cheaper option

- Exposure units that create a vacuum between the screen and glass

- Metal halide or mercury vapour bulbs are a more expensive light source

- Using the sun is a free way to expose screens; you just need it to be a sunny day

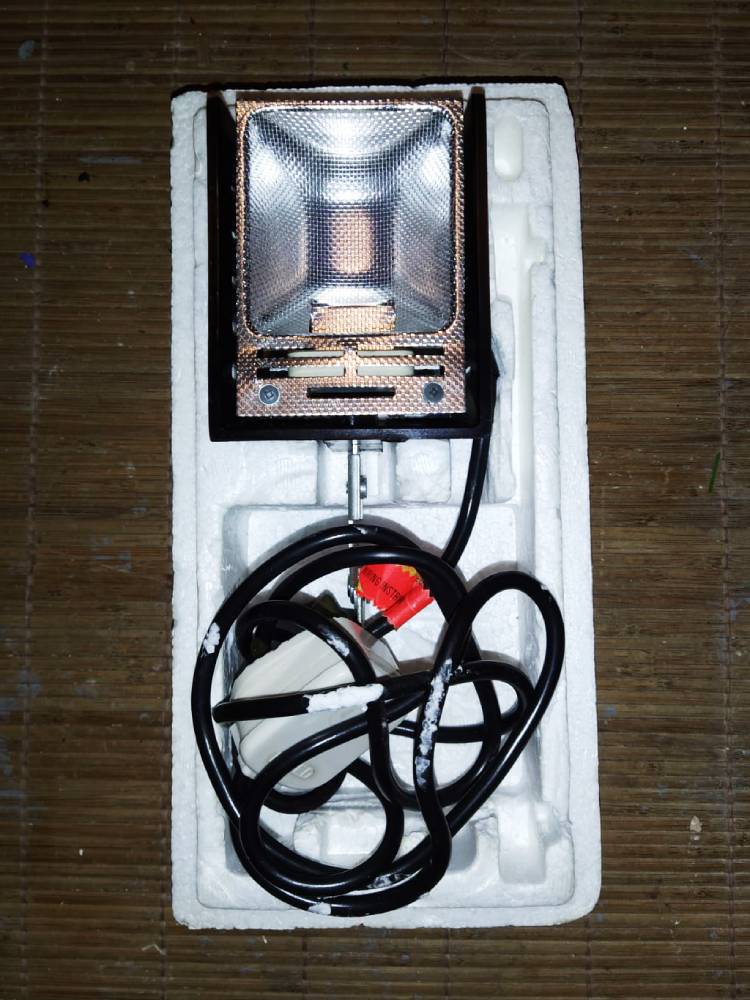

You can either purchase a UV exposure kit/unit, which can be quite expensive, or you can buy a cheap 1000-watt halogen light on eBay and build your own exposure unit for screen printing, which I have pictures of below. You must be very careful with self-built exposure lights as there is always a fire risk when using these. Please don’t leave them unattended.

Tips for Effective Screen Exposure Using 1000-Watt Halogen Floodlights

The units I have built with 1000-watt halogen floodlights have been made with the light positioned about 15 inches away from the screen. A safe bet for exposure time of your screens is roughly 4 minutes. This can vary depending on your setup, so you will need to experiment. Please refer to the table below, which provides a rough idea of different heights and lights.

Two other key points when exposing your screens before printing:

- Place a blacked-out material that sits under the screen and fits the inner edges of the screen frame, pushed very tightly against the underside of the screen mesh.

- Place a sheet of glass on top of the screen, roughly the same size as the outer edge of the screen frame, where you position your film positive to create a seal.

An example of this is a sheet of wood with black foam stuck to it. Bear in mind the heat produced from the light may warp the foam. This ensures the artwork does not move when you expose your screen, which could cause ghosting. This will be covered in more detail in the steps below.

1000w Halogen Light

Current 1000w Screen Printing Exposure Light

A1 Homemade 1000w Light

A1 Size homemade 1000w screen print exposure unit turned on

A1 Homemade 1000w Light

A1 Size homemade 1000w screen print exposure unit

A1 Size Exposure Light

A1 Size homemade 1000w screen print exposure unit being built

Screen Printing Light

1st homemade 1000w screen print exposure unit

Cheap light from eBay

Light in Box

Utilising UV Exposure Units for Screen Printing

UV exposure units are specifically designed for the screen printing industry, offering a consistent and efficient method for exposing screens. These units use ultraviolet (UV) light to harden the emulsion applied to screens, ensuring a clear and sharp image transfer.

Advantages of Using UV Exposure Units:

- Consistency: UV exposure units provide a steady and uniform light source, ensuring that every part of the screen is exposed equally.

- Efficiency: With a set exposure time, these units eliminate the guesswork, resulting in fewer errors and wasted materials.

- Compact Design: Many UV exposure units are designed to be space-saving, making them ideal for both large and small print shops.

- Versatility: These units can accommodate screens of various sizes, allowing for flexibility in the printing process.

- Safety: UV exposure units are enclosed, reducing the risk of direct UV exposure to the user.

When selecting a UV exposure unit, it’s essential to consider the size of the screens you’ll be working with, the unit’s wattage, and any additional features like vacuum systems that can help ensure a tight seal between the screen and the film positive. Proper usage and maintenance of the unit will ensure longevity and consistent results in your screen printing projects.

Harnessing the Sun: Natural Exposure for Screen Printing Screens

Using the sun as a natural source of light for exposing screen printing screens is an age-old technique that remains effective and cost-efficient. While it may not offer the precision of UV exposure units or halogen floodlights, the sun’s ultraviolet rays can still provide satisfactory results for many screen printing applications.

Benefits of Sun Exposure:

- Cost-Effective: No need for electricity or purchasing expensive equipment. The sun is a free resource available to everyone.

- Eco-Friendly: Utilising natural sunlight reduces the carbon footprint associated with electrical equipment.

- Simplicity: It’s a straightforward method that doesn’t require extensive setup or preparation.

Steps for Sun Exposure:

- Preparation: Coat your screen with photo emulsion as you would for any other exposure method. Ensure it’s dried in a dark place before exposing it to sunlight.

- Positioning: Lay your screen flat with the design/film positive facing upwards. Ensure there’s no movement by weighing down the edges or using clips.

- Timing: Exposure times can vary based on the intensity of the sunlight and the specific emulsion used. On a bright sunny day, exposure can range from 10 to 30 minutes. It’s essential to run a few tests to determine the optimal exposure time for your specific conditions.

- Post-Exposure: Once exposed, remove the design and wash out the screen in a shaded area using a gentle spray of water. The unexposed areas should wash out, leaving the design intact.

Considerations:

- Weather Dependency: This method is reliant on sunny weather. Overcast days or unexpected changes in sunlight can affect the exposure quality.

- Inconsistency: The sun’s intensity can vary throughout the day and across different locations, leading to potential inconsistencies in exposure.

Despite its limitations, using the sun for screen exposure can be a viable option, especially for hobbyists or those looking for a more sustainable approach to screen printing.