Affiliate Disclosure: I only recommend products I would use myself and all opinions expressed here are our own. This post may contain affiliate links that at no additional cost to you, I may earn a small commission when you purchase. These commissions help with the running costs of this website, if you do purchase via one of the product links many thanks it is greatly appreciated!

Guide to the Best Squeegees for Screen Printing

Squeegees For Screen Printing

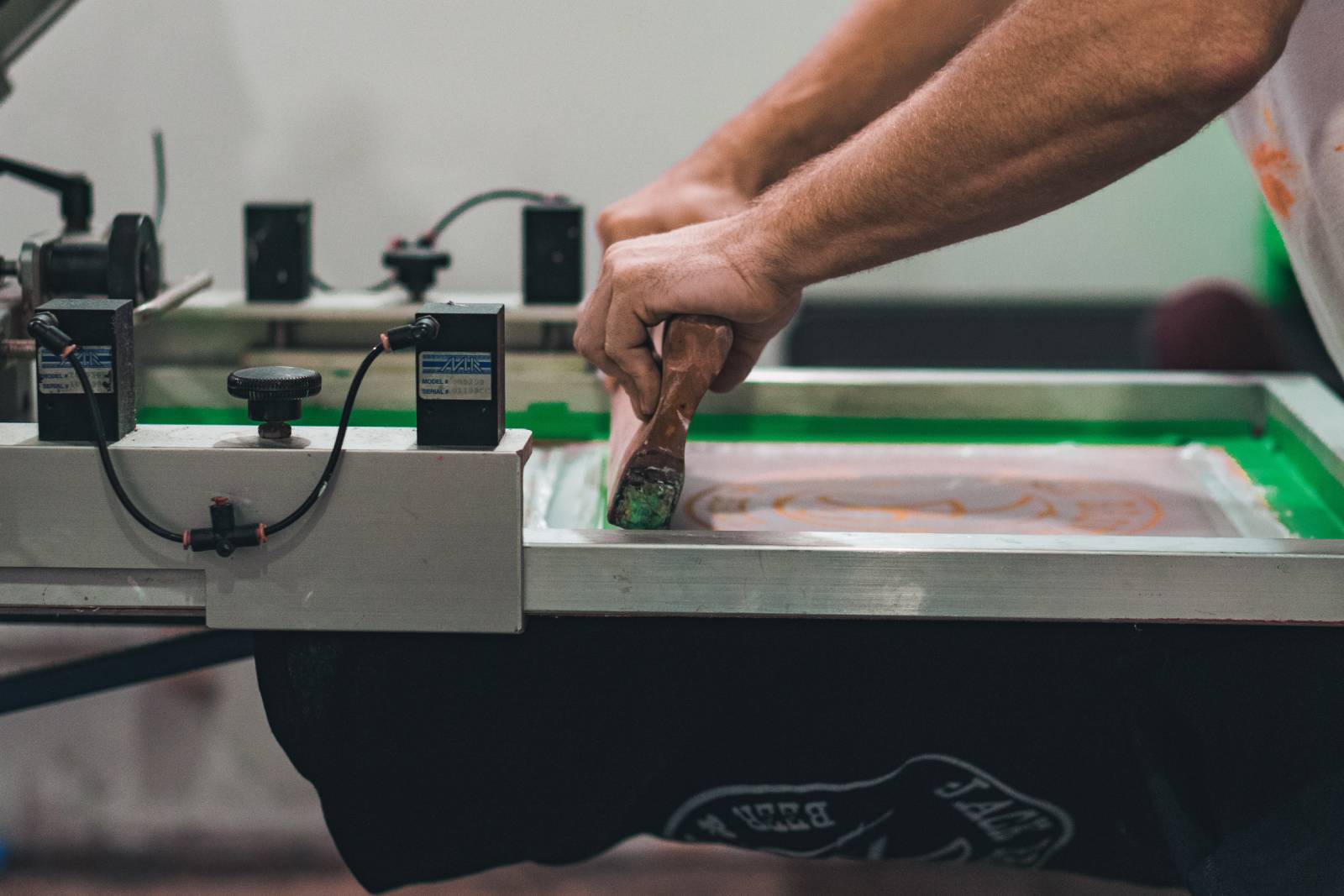

Screen printing, a revered art form and commercial printing method, hinges on the precise use of tools to achieve impeccable results. Among these tools, the squeegee stands out as a pivotal component, determining the clarity, depth, and overall quality of the print. Delving into the world of squeegees, one discovers a plethora of shapes, materials, and rigidity levels, each tailored for specific printing needs. This comprehensive guide illuminates the intricacies of squeegees for screen printing, offering insights into their types, materials, and best practices for optimal results.

There are a variety of rubber squeegee blades available for screen printing. Some are made from synthetic materials, as shown in the image (placement yet to be decided). Our screen printing guide focuses on the 90-degree squared blade, which is optimal for both textile and paper printing. For more insights, refer to the squeegee blade guide from Anatol.

Extra Details About Screen Printing Squeegees

Shape

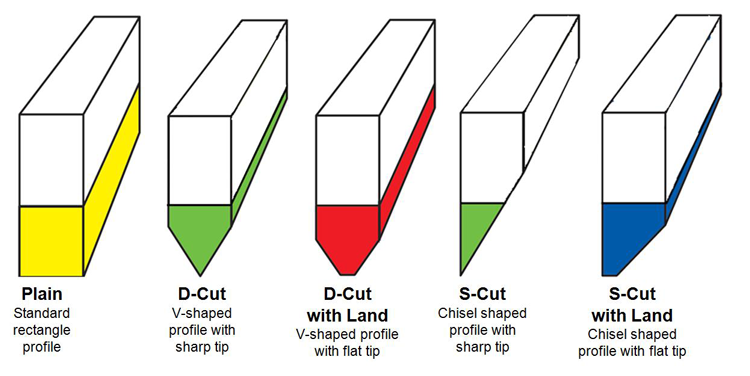

The squeegee blade tip comes in various shapes:

- Square – These straight-edge squeegee blades have a flat bottom. They’re the most prevalent and are suitable for general screen printing tasks.

- Round – Also known as ball-nose squeegees, these are chosen when a more substantial ink deposit is required, such as with heavier substrates or specialty inks.

- Beveled – These squeegees have an angle on one or both sides of the blade, making them ideal for printing on curved or uneven surfaces.

Types of Squeegee blades by beta-chemical.com

Rigidity

Squeegee rigidity is determined by its durometer. A higher durometer indicates a harder blade. Harder blades shear the ink more thoroughly, whereas softer ones leave a more substantial ink deposit.

- Squeegees in the 50 to 60 durometer range are soft and suitable for heavy ink deposits, controlling fibrillation, or using specialty inks.

- The 70 durometer squeegees are medium-hard and are the go-to choice for most general screen printing tasks.

- Hard or ultra-hard squeegees, ranging from 80 to 90 durometer, are perfect for high mesh count screens, fine detail printing, or four-colour process jobs.

Composite squeegee blades combine layers of varying durometers. The printing edge has a lower durometer for smooth screen moulding, while a higher durometer layer provides strength, preventing the squeegee from bending and losing shape.

Squeegee Materials

For a detailed understanding of the materials and types of squeegee blades available for screen printing and their impact on print quality, watch the video below. Floodway Print Co on Youtube offers excellent explainer videos on screen printing, including how to replace the rubber blade on your squeegee.

Squeegees can be crafted from natural rubber, neoprene, or polyurethane:

- Natural Rubber – Traditional and less costly, rubber blades have become less popular as they absorb solvents and degrade quickly.

- Neoprene – Priced between rubber and polyurethane, neoprene blades are favoured for their superior resistance to breakdown compared to rubber.

- Polyurethane – The priciest option, these blades are the most durable, making them suitable for extended jobs and use with automatic or semi-automatic presses.

Handle

For manual screen printers, the squeegee handle is crucial. It should withstand the demands of printing while being comfortable.

- Wooden Handles – Popular for their warmth and comfort, they, however, absorb moisture and solvents, making them challenging to clean. Replacing blades is also typically more cumbersome with wooden handles.

- Plastic or Aluminium Handles – These are easy to clean, and blade replacement is straightforward. Opt for ergonomically designed handles for added comfort.

Other Considerations

- Blade Width – Ensure the squeegee blade extends about an inch beyond your artwork on each side. However, avoid it nearing the screen frame, as it can compromise screen tension.

- Blade Condition – Regularly inspect for nicks, warping, or dullness. A compromised blade can affect print quality.

- Squeegee Care – Blades can absorb moisture and solvents. Clean them promptly after use and maintain a rotation to allow each blade sufficient drying time between tasks.

Understanding the nuances of each squeegee type and its care will enable you to select the perfect one for every screen printing job. Proper squeegee selection and maintenance can significantly enhance your screen printing results.